Supply chain management is key for all organizations to ensure its idea to market (I2M) and order to cash (O2C) operations are efficiently managed. Any gaps in I2M or O2C process groups creates a gap that could lead to significant customer service, delivery and value creation issues in the value chain.

In the second half of past decade industry 4.0 transformation started and alongside supply chain 4.0 transformation also got initiated. Industry 4.0 largely focused on I2M (idea to market) process automations and automations of manufacturing plants. Supply chain 4.0 focused on idea to market as well as order to cash process automations including parts of market to order (customer service) process automations. Supply chain 4.0 also focused on enhancing the warehouse automations to be able to handle various types of orders, shipments, deliveries and regulatory compliance needs.

In the past two years with the Covid outbreak, a lot has changed in terms of how we work and live. Consumer behaviors changed to purchasing online instead of visiting the retail stores. User Ecommerce stores and hubs have gone up significantly covering as much as 70% to 80% of sales done using online stores (Digital).

While all the Ecommerce boom and online shopping trend increased so does the challenge and complexity for supply chain management (SCM) team increased. SCM team has to ensure deliveries are made appropriately in time and trends shift from large orders to distributors and retailers to small orders direct to consumers (D2C).

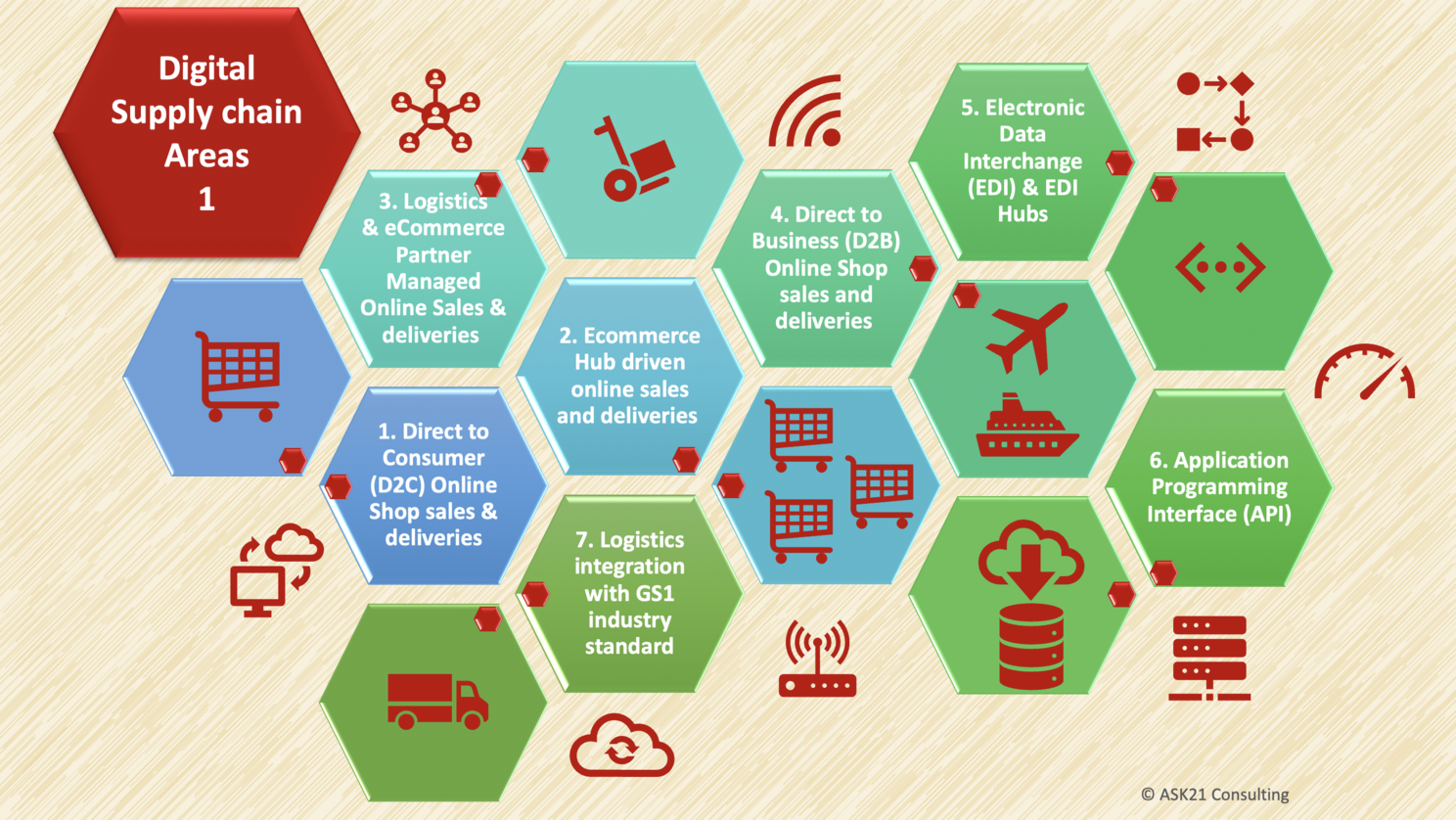

The Ecommerce boom also created new avenues for organizations to build more Direct to Consumer orders handling and delivery mechanisms. There were 7 different avenues opened up for managing and operating online sales seamlessly across the value chain. Let’s go through the part 1 of seven digital supply chain transformation areas for organizations,

1. Direct to Consumer (D2C) Online Shop sales and deliveries – This included organizations deploying more D2C (direct to consumers) shops across all countries even where there was low value creation business case to do so, as they envisioned the need would increase in the coming years and it’s better to prepare upfront.

2. Ecommerce Hub driven online sales and deliveries – Outsourcing and managing the Market to order and Order to cash operations through eCommerce hubs (E.g., Shoppe, Lazada, JD and many more) in various countries. This ensured reduced load on SCM and logistics partner as they didn’t have to cope with up and down streams of online orders and deliveries on day-to-day basis. It also gave them an advantage to use respective partner eCommerce platforms for orders as well as returns, cancellations, refunds (customer service) to some extent.

3. Logistics and eCommerce Partner Managed Online Sales and deliveries – The 3rd avenue was to tie up with logistics & eComm partners (E.g., Urban Fox, YCH, Lotte etc.) that can manage both the organization owned D2C shops as well as multiple eCommerce hubs (E.g., Shoppe, Lazada, JD and many more). This further ensured that SCM teams burden reduced in terms everyday monitoring and tracking of so many online platforms and all the complexities attached.

4. Direct to Business (D2B) Online Shop sales and deliveries – On one end the need for online sales direct to consumers increased but it also triggered a need for online sales to distributors, retailers and in some cases even online partners. The need arises from online customers (distributors, retailers, shop owners etc.) needing a flexible platform to order on demand as and when they needed the stocks to fulfill the end consumer’s needs.

5. Electronic Data Interchange (EDI) and EDI Hubs – For making the order to cash process seamless, most customers (especially large distributors and frequent ordering customers) asked to connect their ordering systems (mostly ERP systems like SAP, Oracle etc.) to organizations ordering systems (mostly ERP systems like SAP, Oracle etc.) using Electronic Data Interchange (EDI) and in many cases through the EDI Hubs. EDI Hubs are EDI service providers that connect customer systems with the sellers organization’s systems. This ensured orders, acknowledgement and invoices seamlessly flow between systems without any need for reentering the order in any online platform.

The customers that didn’t have EDIs possible or have not so frequent ordering pattern, chose to go with D2B shops option as the D2B shops also allowed order upload, order copy, reorder options.

6. Application Programming Interface (API) – The need for Application Programming Interface (API) came up as going online means dealing with too many distributed and segregated systems. For eCommerce and SCM order to cash processes to work seamlessly in real time or even near real time, there has to be integration between multiple systems.

The internal organization managed systems (ERP, eCommerce shop, CRM etc.) can be tightly integrated to ensure updates from one system to other systems happens seamlessly.

The integration with the partner systems (logistics and ecommerce partners) can be made tight or loosely coupled based on the type of system and need. If loosely coupled would mean there will be a time lag between online order/activity and when it gets synchronized to organization’s systems.

7. Logistics integration with GS1 industry standard – For supply chain management to work efficiently, it is important that the organization’s logistics systems and logistics providers warehouse management and transportation systems are integrated with GS1 industry standard interfaces. The GS1 organization has created a worldwide standard for logistics organizations to function efficiently. These standards ensure timely messaging between systems to keep the inbound (from factory to shipping to warehouse) and outbound (from warehouse to delivery partner to customer) processes fully automated and synchronized.

Each of the above seven areas can be detailed out in separate articles as each area is very wide with its own approach, platforms and benefits. For keeping the article limited in length, let’s keep the explanations high level only.

Digital supply chain 4.0 in conjunction with industry 4.0 is still in process of being deployed and improved by many organizations while top organizations might have already achieved the needful digital transformations and are now continuing improvements.

Digital supply chain 5.0 is on the horizon as we move towards Web 3.0 and 5G lightning internet speeds making everything connected, always on and seamlessly reachable across the globe. Digital supply chain 5.0 will bring hyper automation and autonomous warehouse management and even autonomous deliveries. Robotics, Robots, Artificial Intelligence and Autonomous vehicles will change the way supply chain is managed and customers are served.