Value stream mapping (VSM) is a lean management method and tool for analyzing the business process and/or the entire value chain (value stream) of the business. It consists of core business process review and optimization from its current state to future state by eliminating waste in the process.

VSM can be also considered as a process flow map consisting of product, people and tools reflected across the process stages including issues and gaps identification. It is generally drawn with a group of people that operate as part of the flow and play a role in managing respective process stage deliverables (outcomes). The process selected must be focused on delivering certain specific value to the customer.

The core purpose of VSM is to identify and remove waste in the value chain and in return increasing efficiency and effectiveness of the value chain. By removing waste the value chain becomes optimized and faster than before resulting in productivity gain and achieving its desired outcomes with in lesser time and reduced number of resources.

Lean focuses on creating superior value for the customer while still using fewer resources to get it done. In turn ensuring the entire value chain is streamlined for efficient performance and delivery.

Identifying and eliminating waste is the core part of lean management. There are mainly seven types of waste in Lean management namely,

1. Transportation – Transportation waste is related to any movement of materials, supplies and resources that does not add any value to delivering customer needs. E.g., Extra trucks, fork lifts, unnecessary movement of materials and supplies etc.

2. Inventory – Inventory waste is related to any excess supplies that does not add any value to delivering customer needs. E.g., Excess stocks storage, Excess stock at production lines, Excess stocks in warehouse etc.

3. Motion – Motion waste is attached to any unnecessary movement of resources, people and machines that does not add any value to delivering customer needs. E.g. People movements without need, machine movements without need, back and forth movement to get tools or parts resulting in waste of time etc.

4. Wating – Waiting waste is attached to long periods of elapsed time waiting between tasks and stages for people, machine, materials that does not add any value to delivering customer needs. E.g., People waiting for machine or parts, People waiting for each other to start work, Poor planning having too much free time in the plan etc.

5. Over Production – Over Production is attached to too much advance production of goods that are not requested by customer. E.g., Poor demand planning, Too fast production or advance production etc.

6. Over Processing – Over Processing is attached to additional efforts put on task that does not add any customer to meeting customer needs. E.g. too many approvals for each request, endless analysis of needs etc.

7. Defect – Defect is attached to rework needed to resolve defect in the product or service to meet customer needs. E.g. Product quality issues, non-standard work processes, no clarity and checks on customer needs etc.

While there are mostly only seven types of waste in the process, in real life situations there could waste in the process related to systems as well, E.g. Unsecured system, Wrong authorizations etc.

As VSM started as part of Lean its primary use has started in manufacturing and industrial processes. From past decade VSM has been used across all business sectors and divisions, E.g., Healthcare, Consumer goods, IT, Supply chain management, Finance, Customer Service, Logistics etc.

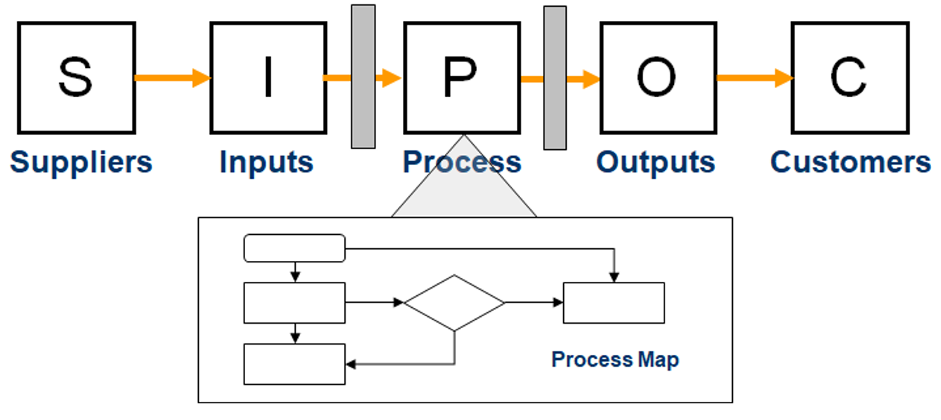

Value stream mapping starts with the use of SIPOC method considering Suppliers, Inputs, Process, Outputs and Customers are fully covered in the process map and reviewed. SIPOC is a high level view of a process consisting of Suppliers, Inputs, Process, Outputs and Customers.

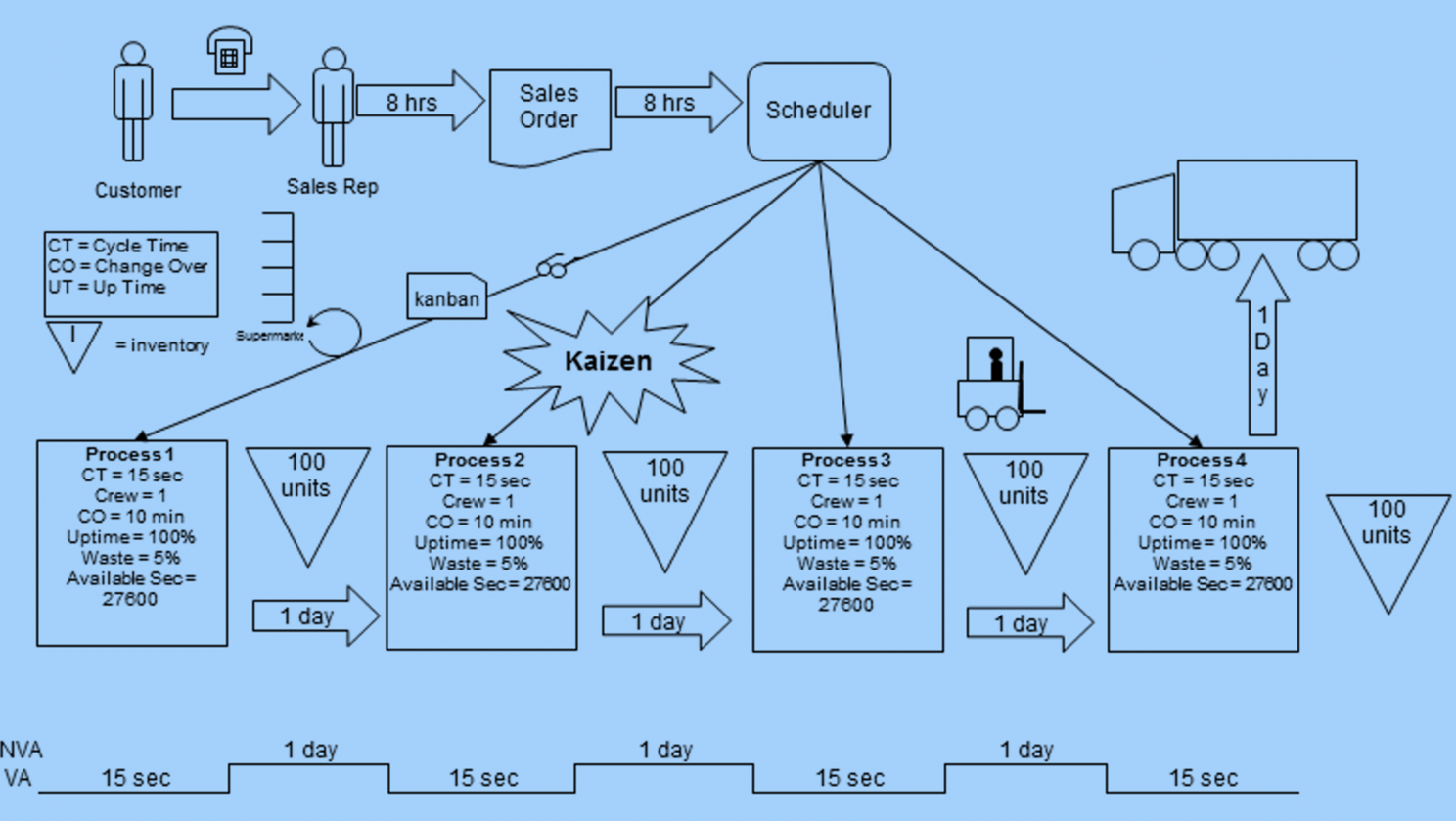

Here is a brief overview of VSM process mapping model template overview as per Lean standard, with brief explanations on how to create it,

Here is a brief overview of VSM process mapping model example overview as per Lean standard,

How is VSM arranged

VSM consists of all the key stakeholders of the value stream at each stage. It is generally arranged as a half day to 3 days workshop depending on the size and complexity of the value stream mapping.

The process is initiated with the current process map which starts with ensuring the need for VSM is clear for every one involved.

For making the VSM need clear to all, before the workshop a core team arranging the VSM creates a VSM charter consisting of a one-page overview (similar to project charter) specifying the problem, purpose, who will lead the session, who needs to be involved, who is sponsoring etc.

Here is formal process steps for achieving VSM,

1. Define the need – This step focuses on defining the need for value stream mapping session. It includes identifying stakeholders, define VSM charter, planning the event schedule and participants, complete all the preparations (like high level process views, logistics, prints, post its, markers, stickers) etc.

2. Map The Current State – This stage starts in the VSM workshop where the team begins with,

a. High level SIPOC process overview specifying process stakeholders, inputs, output and major steps. This helps everyone understand the current state at high level easily.

b. Next the team starts working on detailing out entire value chain with more granular details like who is involved, what is the throughput time, what gaps or issues are faced, what is done well and what needs improvement.

c. The focus is always on process and delivering value to customer, there is no pin pointing on any individual or team names.

d. Lean wastes in the process are identified and documented along with possible action.

e. The process is managed using post its and stickers for voting as well as capturing inputs.

f. At the end of the day or during breaks the core team of process or VSM leads collate all the inputs either as pictures or even electronically drawing it and capturing possible actions.

3. Create The Future State – This stage starts in the VSM workshop part 2 and sometimes day 2, where the team begins with,

a. Creating the future state map together as a team. The major steps might be same or changed or reduced based on current state see.

b. The team collectively goes through the lean wastes identified and how those can be removed to make the process (value chain) effective and efficient.

c. The future state can also be largely automating all possible non value added manual steps in the value chain and hence achieving improved speed with reduced resources needed to manage.

d. The process is managed using post its and stickers for voting as well as capturing inputs.

e. At the end of the day or during breaks the core team of process or VSM leads collate all the inputs either as pictures or even electronically drawing it and capturing possible actions.

4. Prepare the Implementation Plan – This stage starts in the VSM workshop part 3 and sometimes day 3, where the team begins with,

a. Reviewing the action plan and ensuring each action has an owner and date attached to it.

b. The team also prioritizes the actions in order of which action will create how much value for the customer.

c. The team also prepares the high-level future state readiness schedule with owners and dates for completion.

d. Both the action plan and future state readiness schedule are agreed with all participants of the workshop and the stakeholders.

e. The VSM leads, work out the report out deck capturing full workshop details inputs, outputs and actions moving forward. Part of the deck is also the costs and resources needed, work cadence and reporting schedule post workshop.

This marks the end of the workshop but the actual work starts post workshop to close the gaps and implement the future state process flow. The team continues the cadence and implements the future state. Post that continuous improvement cycle starts with Kaizen, Daily Management and PDCA (Plan Do Check Act) cycle.

The VSM sessions are revisited every 9 to 12 months to review and improve the process value chain continuously to adapt and deliver superior value to the customer.

VSM has many benefits for the organization. VSM Benefits include, bringing people together as one team, improved understanding of the value chain and what matters most for the customer, removal and reduction of lean waste across the value chain.