Lean management is a framework for reducing waste in the process of delivering value for the customer(s). Lean thinking concept and framework came to existence in the 1990s. It became largely popular and adopted by most organizations in the last decade. Manufacturing plants adhered to lean thinking and management, way back since the 1990s decade.

It works on the philosophy of providing value to the customer through value creation process consisting of zero waste. It reduces costs, improves speed of delivery with quality output by getting rid of all non-value added activities in the process that the customer is not willing to pay. It is not a cost reduction program but it focuses on optimising the entire end to end value chain of the organization.

Lean management is largely related to creating a lean culture across the entire end to end value chain process of the organization to deliver superior value for the customer and reduce non value added activities that the customer is not willing to pay. By doing this enhance and optimize the entire end to end value chain, reduce costs and improve quality. Also freeing up time for people and resources to do more meaningful work that matters most for creating value for its customers.

Lean management opens doors for organizations that seek continuous improvement, organizations that want no waste manufacturing and for organizations and divisions that want their value chain processes improved to deliver superior value to the customers.

Lean focuses on identifying the waste in the process and uses five principles namely,

1. Identify Value – Identifying value is attached to understanding that the customer want quality delivery and doesn’t want to pay for any waste along the entire process in the organization.

2. Map the Value Stream – Mapping the end to end value stream along with the time and resources it takes at each step. This helps in identifying and eliminating the waste (E.g. waiting time, time lapse etc.)

3. Create Flow – Creating the flow focuses on ensuring just in time creation and delivery. Organizations should not continuously create the flow and produce products, rather the flow must be created and kept efficient to delivery based on actual demand of the customer. Thus reducing the over production, transportation and storage cost burdens.

4. Establish Pull – Establish pull is also attached to just in time delivery thinking. Across the value chain the work must be done based on pull system to ensure based on actual need the work is done and not endlessly.

5. Seek Perfection – Seeking perfection is attached to continuous improvement across the entire end to end value chain. These improvements can be small size incremental changes to eliminate waste and optimize process. These improvements are done using Kaizen. Kaizen ensure lean thinking and culture get deeply rooted in the organization and people making it second nature to think lean.

Lean focuses on creating superior value for the customer while still using fewer resources to get it done. In turn ensuring the entire value chain is streamlined for efficient performance and delivery.

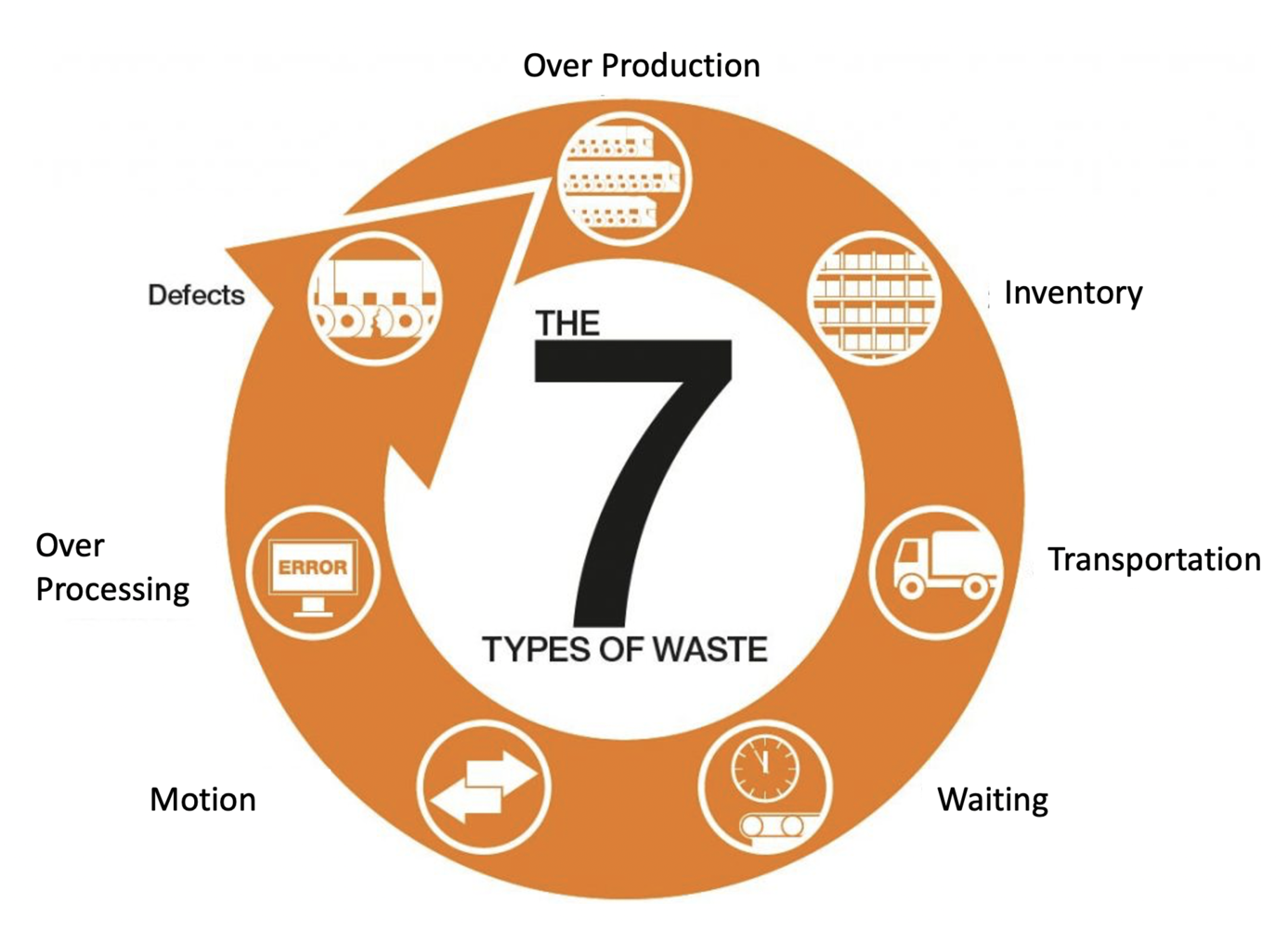

Identifying and eliminating waste is the core part of lean management. There are mainly seven types of waste in Lean management namely,

1. Transportation – Transportation waste is related to any movement of materials, supplies and resources that does not add any value to delivering customer needs. E.g., Extra trucks, fork lifts, unnecessary movement of materials and supplies etc.

2. Inventory – Inventory waste is related to any excess supplies that does not add any value to delivering customer needs. E.g., Excess stocks storage, Excess stock at production lines, Excess stocks in warehouse etc.

3. Motion – Motion waste is attached to any unnecessary movement of resources, people and machines that does not add any value to delivering customer needs. E.g. People movements without need, machine movements without need, back and forth movement to get tools or parts resulting in waste of time etc.

4. Wating – Waiting waste is attached to long periods of elapsed time waiting between tasks and stages for people, machine, materials that does not add any value to delivering customer needs. E.g., People waiting for machine or parts, People waiting for each other to start work, Poor planning having too much free time in the plan etc.

5. Over Production – Over Production is attached to too much advance production of goods that are not requested by customer. E.g., Poor demand planning, Too fast production or advance production etc.

6. Over Processing – Over Processing is attached to additional efforts put on task that does not add any customer to meeting customer needs. E.g. too many approvals for each request, endless analysis of needs etc.

7. Defect – Defect is attached to rework needed to resolve defect in the product or service to meet customer needs. E.g. Product quality issues, non-standard work processes, no clarity and checks on customer needs etc.

While there are mostly only seven types of waste in the process, in real life situations there could waste in the process related to systems as well, E.g. Unsecured system, Wrong authorizations etc.

Lean uses various tools to manage wastes. Here is a list of them with one liners,

1. 5S + 1 – Consists of Seiri (sort), Seiton (Simplify), Seiso (Sweep), Seiketsu (Standardize), Shitsuke (Sustain) and Safety.

a. Seiri (Sort) – Sort only what is needed where is needed.

b. Seiton (Simplify) – A place for everything and everything in its place.

c. Seiso (Sweep) – Clean the workspace and keep it clean.

d. Seiketsu (Standardize) – Standardize the first three “S.”

e. Shitsuke (Sustain) – Stick to the first 4S.

f. Safety – Provide a safety environment for everybody.

2. Value Stream Mapping – Value stream mapping is the process of full end to end value chain mapping of current state and future state process. The emphasis is on identifying and eliminating waste in the process to make it optimised and efficient to deliver superior value to the customer.

3. Kaizen – Kaizen is used for continuous improvement across the entire value chain. Improvements are generally small and incremental. Kaizen tools like PDCA (Plan Do Check Act) cycle, 5 Whys, Ishikawa diagrams are used.

4. Kaizen Blitz – Kaizen blitz is also called as Kaikaku, it is short timescale kaizen. Focused on events, small and rapid improvements.

5. Takt – Takt time is used for pull scheduling and improving efficiency.

6. Jidoka – Jidoka is used for improving quality at source through Autonomation (Intelligent automation) as well as for defects and alerting.

7. Kanban – Kanban is card based system for just in time scheduling for efficient pull system.

8. Poka-yoke – Used for defect prevention of three types (contact, fixed value and motion)

9. SMED – Single-Minute-Exchange of Die – Used for quick changeover of dies for improving the flow.

Lean also has problem solving and daily management tools for effective problem identification and resolutions while daily management ensure adherence and tracking of metrics for improving processes and results with close daily monitoring cadence.

Lean management can applied to all industries and sectors as well as all business functions and divisions. Lean is cultural change where the entire organization adheres to continuous improvement mindset by using Lean management principles and tools.